Moisture in Airlines

Moisture in Airlines

This is a typical service call that we receive. The customer is concerned because their Compressor, or Compressors are running constantly, and there is a lot of water in their airlines. The water is contaminating the air tools and other pneumatic devices that they use, as well as making tire inflation impossible.

Usual culprits are failed drain valves on Tank and Filters, failed Refrigerated Air Dryers, or in some cases, drain valves are unplugged, or components are bypassed.

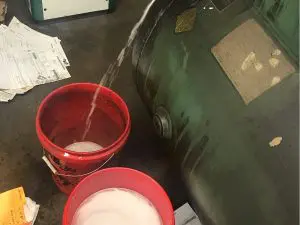

In this instance, a total of about 40 gallons of nasty, smelly, condensate comprised of water and oil carryover from the Compressors was drained from this system. The Compressors were under a heavy load because the storage, or “receiver” tank was half full of water, so the Compressors had to work harder to try to maintain system pressure.

How To Dispose of Condensate Water

Disposal of the oil-water solution that is produced by Air Compressors is regulated by local, as well as EPA regulations. This condensate drain material must be properly treated with the use of an Oil-Water Separator which removes the oil from the water. The water is now safe to be put into the sewer drains. The oil is collected and disposed of properly as “waste oil”.