Air Compressor Problem Solving with Mr. Airhead

To operate a factory, shop, health care facility, or 99.99% of all industries, there are four utilities that must be available.

To operate a factory, shop, health care facility, or 99.99% of all industries, there are four utilities that must be available.

- Electricity

- Water

- Gas

- Compressed Air

The “fourth” utility Compressed Air is frequently overlooked until it is not available. When business comes to an abrupt stop, the lack of Compressed Air becomes the number one priority and utility. It is somewhat typical to find that no one is aware of the importance of Compressed Air to the operation of the plant or facility, until it stops working. This brings us to the “million-dollar question”. Do we have a backup Compressor to run the operation until we can get our primary system fixed?

Compressed Air Backup System

Without a backup system, a business is faced with production loss and costly downtime. Depending on the type of business, this can mean thousands of dollars per day, or per hour, in lost production and revenue. Idle workers and support staff possibly facing lost wages. Summary = Disaster

The solution is simple; a backup Compressor must be available at all times. With a full backup system in place, there will be no downtime or lost production. The upfront cost of purchasing two systems in order to have the backup required is paid for by the prevention of downtime costs.

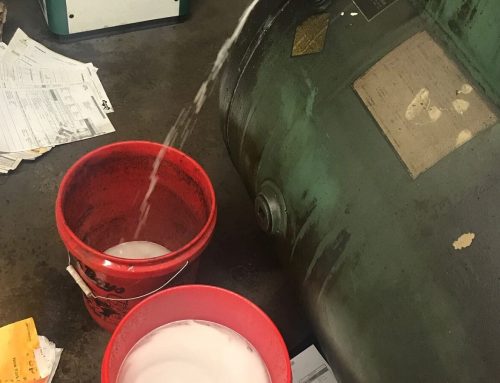

Pictured below is a properly designed system consisting of two complete Chicago Pneumatic 30 HP Compressor / Dryer / Receiver tank units also known as “All-In-One” units. In case of a failure of one system, the backup system comes online automatically, with no production interruption, or downtime.

Published by:

Ed Keller – Compressed Air Services

934 Sweeney Drive Suite 1A

Hagerstown, MD 21740

(800) 905-4705

(240) 420-8132