Handy Rules Of Thumb For Estimating

Air Compressors:

1. Air compressors are normally rated to deliver 4 to 5 CFM per horsepower at 100 PSIG discharge pressure.

2. Depending on the the size of the system, compressed air costs about 25 to 42 cents per thousand cubic feet of free air ingested by the compressor (including operating and maintenance costs).

3. A 50 horsepower compressor rejects approximately 126,000 BTU per hour for heat recovery.

4. Motor amperage draw:

- 1 Phase

- 3 Phase

✓ 15 V – 10 Amps per HP

✓ 230 V – 5 Amps per HP

✓ 230 V – 2.50 Amps per HP

✓460 V – 1.25 Amps per HP

Air Receivers:

1. Size air receiver tanks for about 1 gallon capacity for each CFM of rotary compressor capacity. Standard receiver tank sizes are listed below:

Gal.

30

60

80

120

200

240

Dimensions

16″ x 38″

20″ x 48″

20″ x 63″

24″ x 68″

30″ x 72″

30″ x 84″

Gal.

400

660

1060

1600

220

2560

Dimensions

36″ x 96″

42″ x 117″

48″ x 144″

54″ x 170″

60″ x 190″

60″ x 220″

2. Cubic Feet: Gallons x 0.13368

Water Content:

1. The water vapor content at 100¼ F of saturated compressed air is about two gallons per hour for each 100 CFM of compressor capacity.

2. Every 20¼ F temperature drop in saturated compressed air at constant pressure, 50% of the water vapor condenses to liquid.

Water-Cooled Aftercoolers:

1. Most water-cooled aftercoolers will require about 3 GPM per 100 CFM of compressed air at Discharge Air Tempera- ture at 100 psig.

Compressor Discharge Temperature (Before Aftercooling):

1. Approximate discharge temperatures (before aftercooling) at 80¼ F ambient:

| PRESSURE | 100 PSIG | 150 PSIG | 200 PSIG |

|---|---|---|---|

| Single-Stage | 510 | 615 | — |

| Two-Stage | 325 | 365 | 395 |

| Rotary (Oil-Cooled) | 180 – 200 | 190 – 205 | 200 – 215 |

Horsepower & Power Cost:

1. Every 2 psig change in pressure equals 1% change in horsepower.

2. Most AIR MOTORS require 30 CFM at 90 psig per horsepower.

3. 10¢/ KWH Electric Power Rate = $806/ Year for 1 HP/3 shift Constant Run.

4. KW = HP x 0.7457

Saturated Compressed Air

1. At 100 psig every 20¼ F increase in saturated air temperature doubles the amount of moisture in the air.

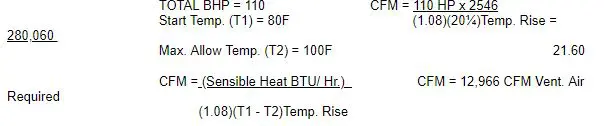

Ventilation Required

The following formula will estimate the required ventilation air in cfm to adequately control ambient heat rejection from an air compressor Ð BE SURE TO USE FULL ABSORBED HORSEPOWER!

EXAMPLE: